Quality Assurance

Product quality is the first implementation standard.

Building a competitive advantage through quality management.

We at Hualian Glass have a department specializing in quality control to guarantee the quality of the products that we provide. Our quality control and manufacturing departments work in tandem in each and every phase and process, Raw materials, including the melting, forming, inspection and packaging process —together they ensure the quality of the final product.

Advanced testing equipment is one of the important tools to ensure product quality.

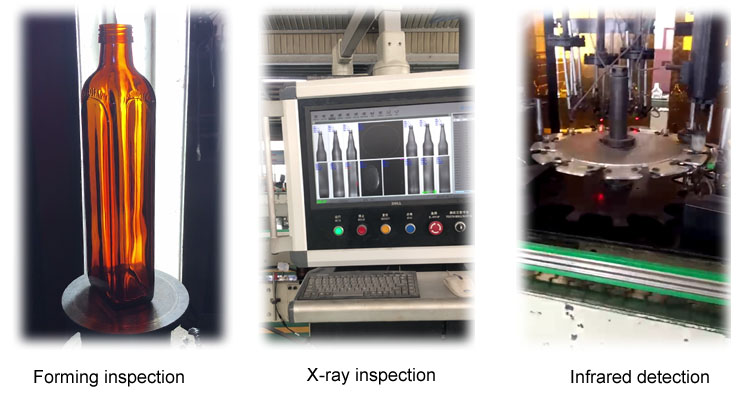

Forming inspection

Forming inspection is the inspection step after the product is formed from the mold. Through the inspection, various problems of the mold can be found to ensure that the appearance of all products meets the requirements.

X-ray inspection

X-ray inspection is to check the bubbles, cracks, wrinkles and other defects on the glass bottle through X-ray imaging. If found that do not meet the standards, the defective product is automatically thrown away.

Infrared detection

Infrared detection Is uses infrared rays to irradiate the bottle mouth. If defects such as mouth cracks or out of roundness are found, the defective product is automatically thrown away.